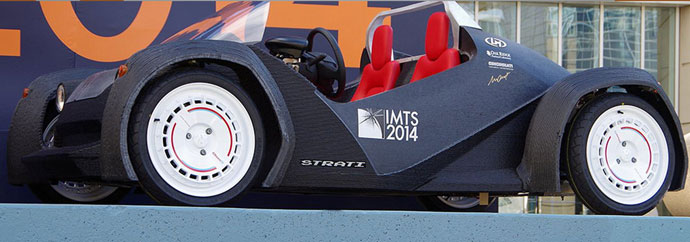

It’s bodywork may look a little rough around the edges, and it would need a roof to cope with the British winter, but these failings can be forgiven because the Strati is the world’s first 3D-printed electric car.

A group of engineering companies built the life-size, working 3D-printed prototype vehicle in 44 hours using a process called direct digital manufacturing. The body, which comprises over 200 printed layers of carbon fibre-reinforced ABS plastic, was fitted to the chassis from a Renault Twizy.

The 50 mph Strati may not have a roof, but it boasts an electronic engine immobilizer, regenerative braking and all-round disc brakes.

The project aims to demonstrate the viability of cutting-edge technology to create sustainable, large-scale processes for the car industry.

Breaking the mould

Hugo Spowers plans to transform the way we use our cars by replacing outright ownership with a system similar to a mobile phone contract. His approach to car making is radically different to any other manufacturer, not least because the designs are ‘open source’, or freely available to other car makers who would like to build upon the technology. The designers hope to encourage an environmentally-sustainable alternative to conventional car manufacturing, which sees cars bought, driven into the ground and junked.

0 Comments View now